Product Gallery

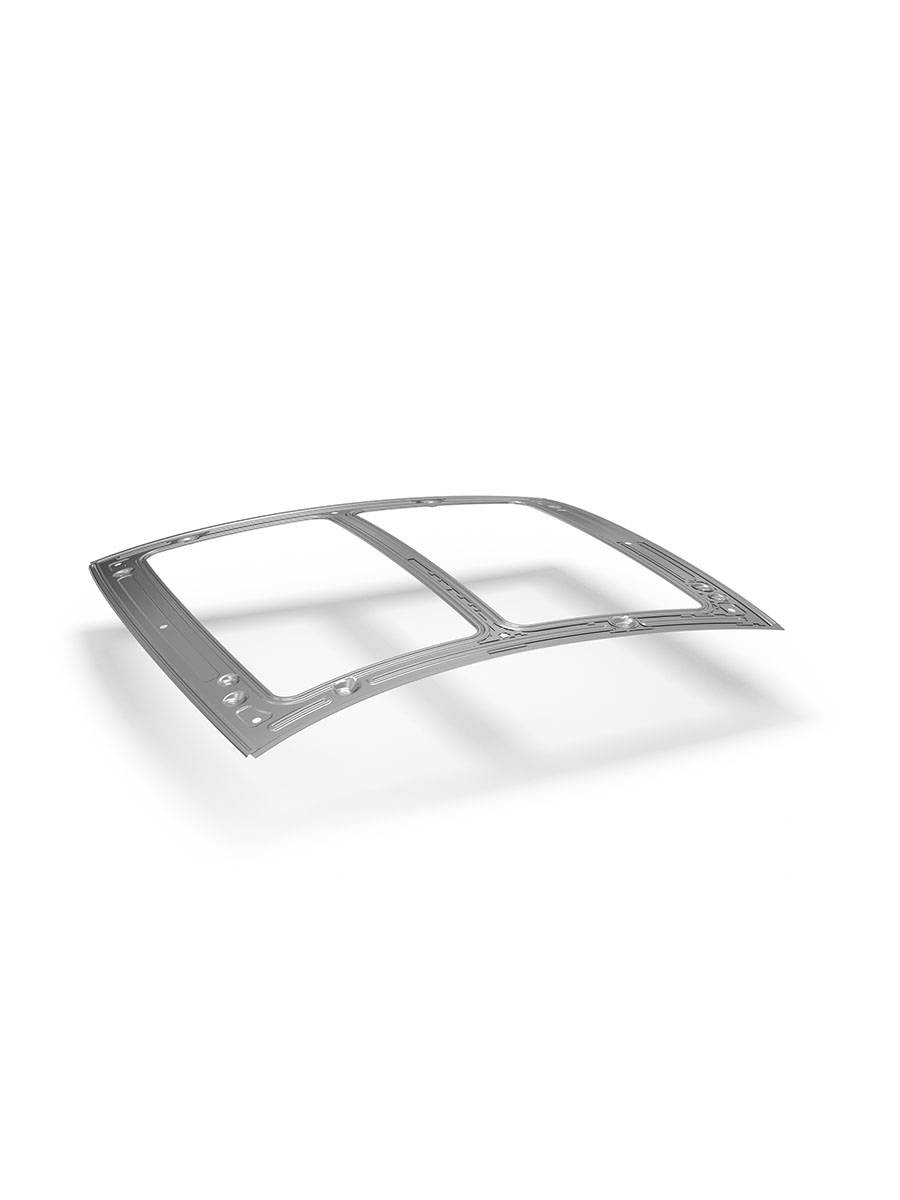

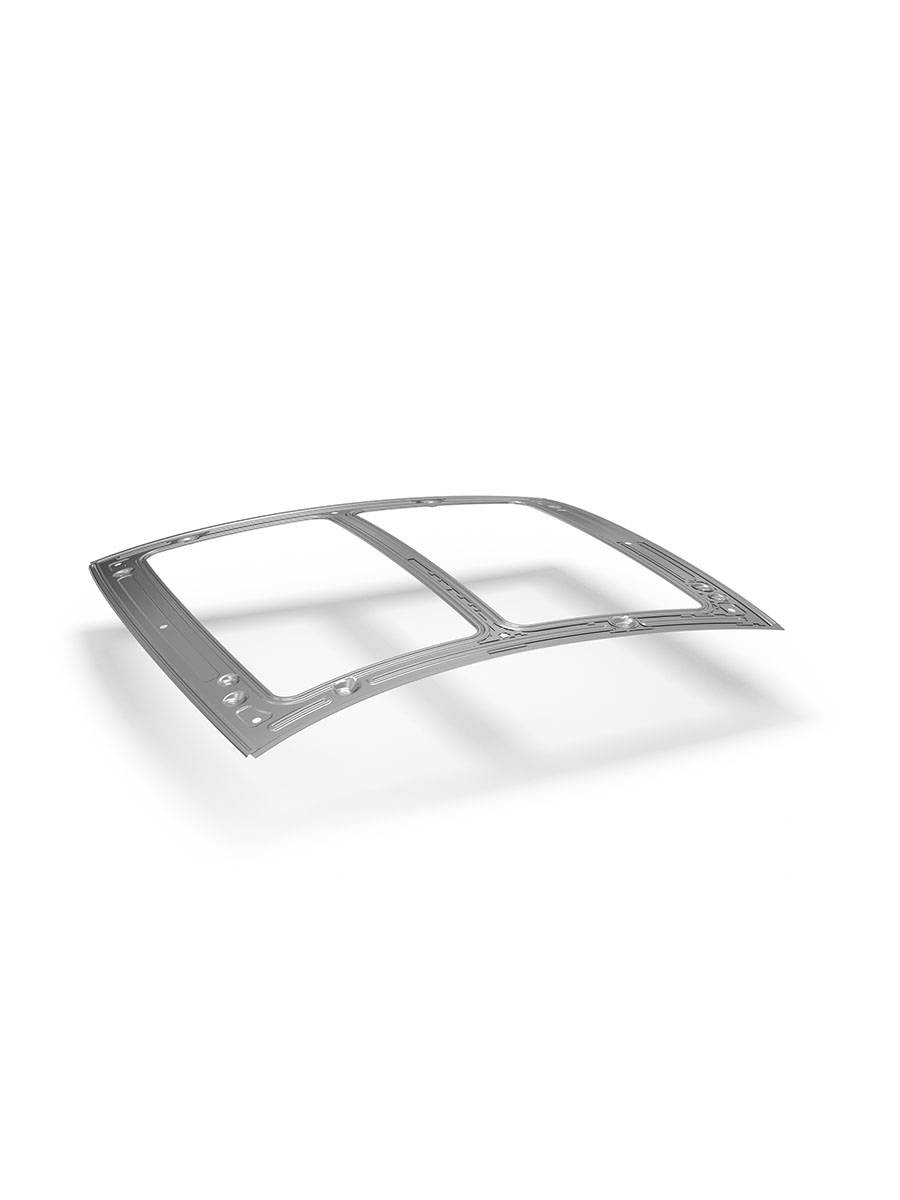

ROOF FRAME

High quality standard required for this die for aluminium part.

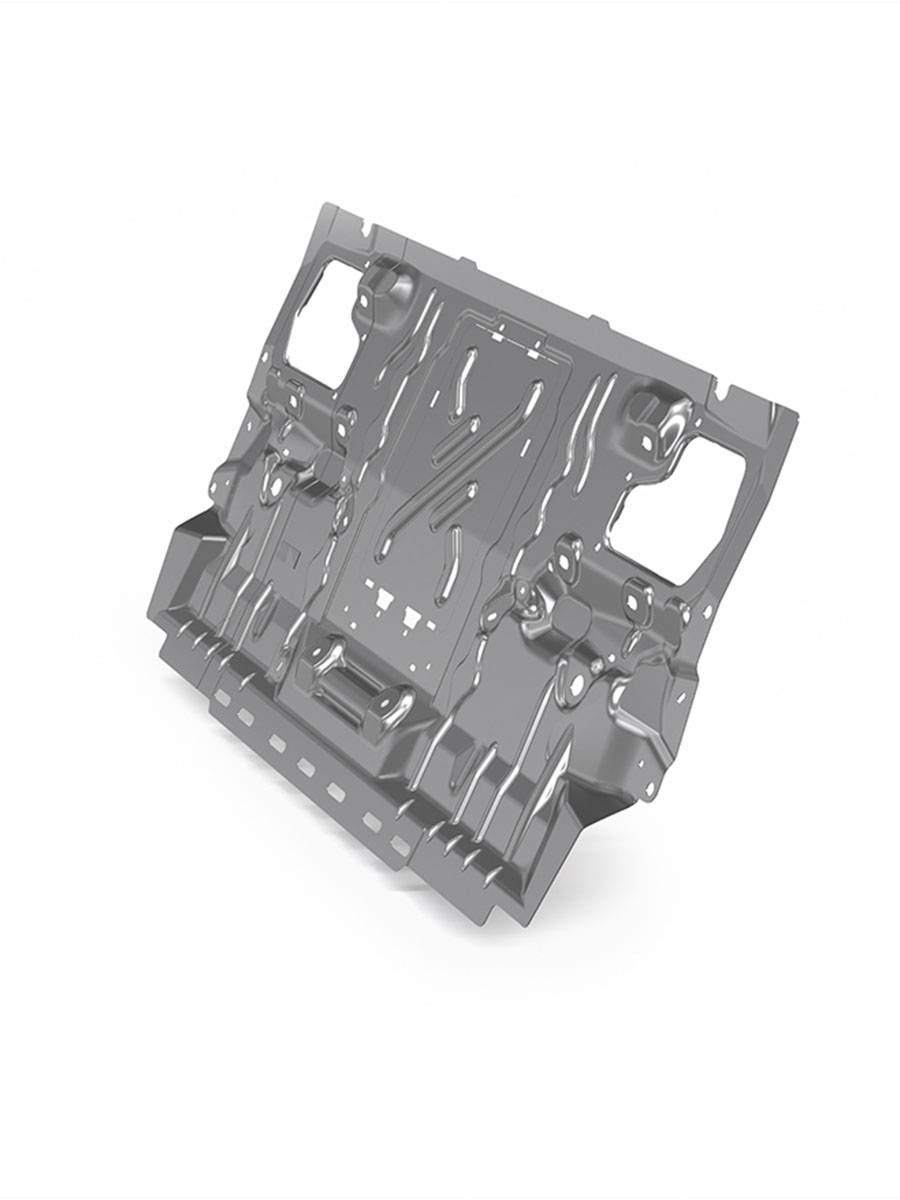

TUNNEL

Technical complexity due to the springback related to part feasibility

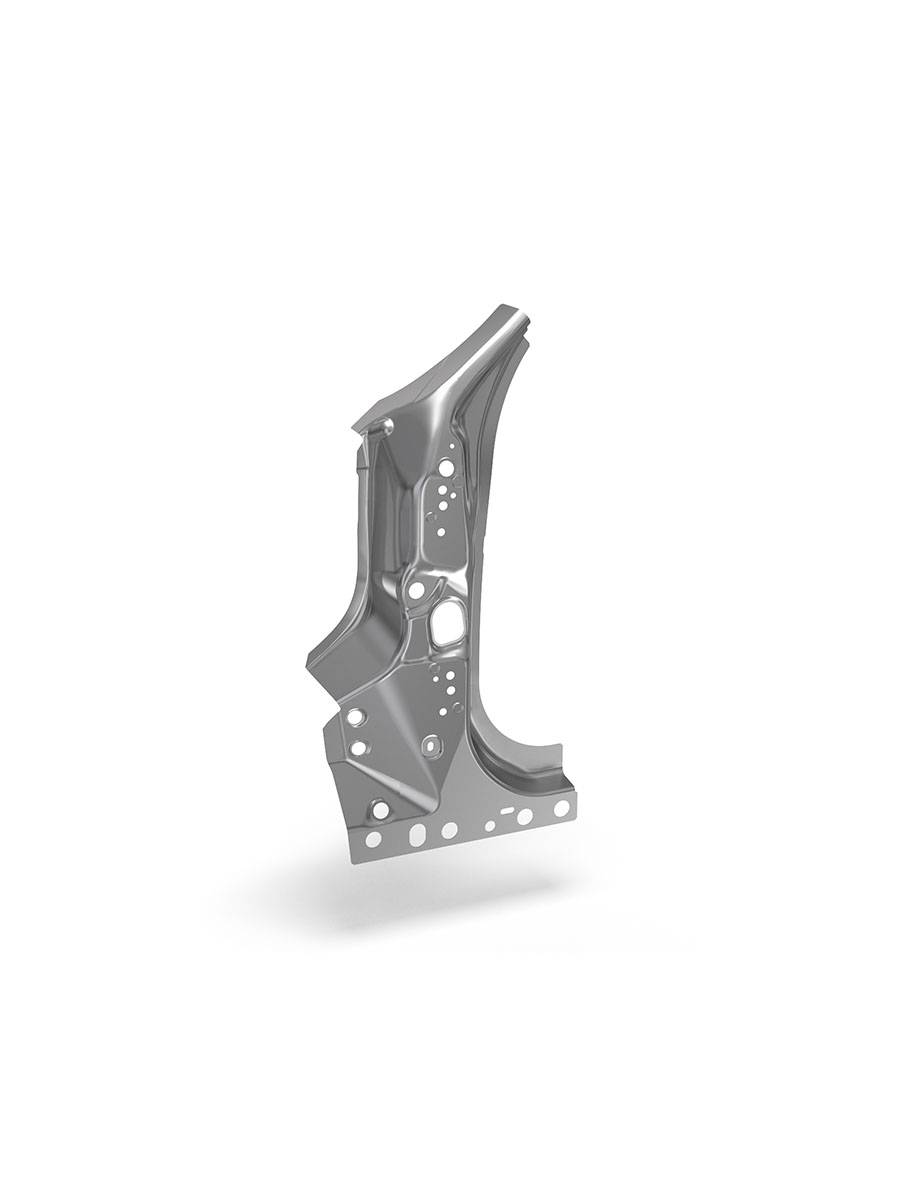

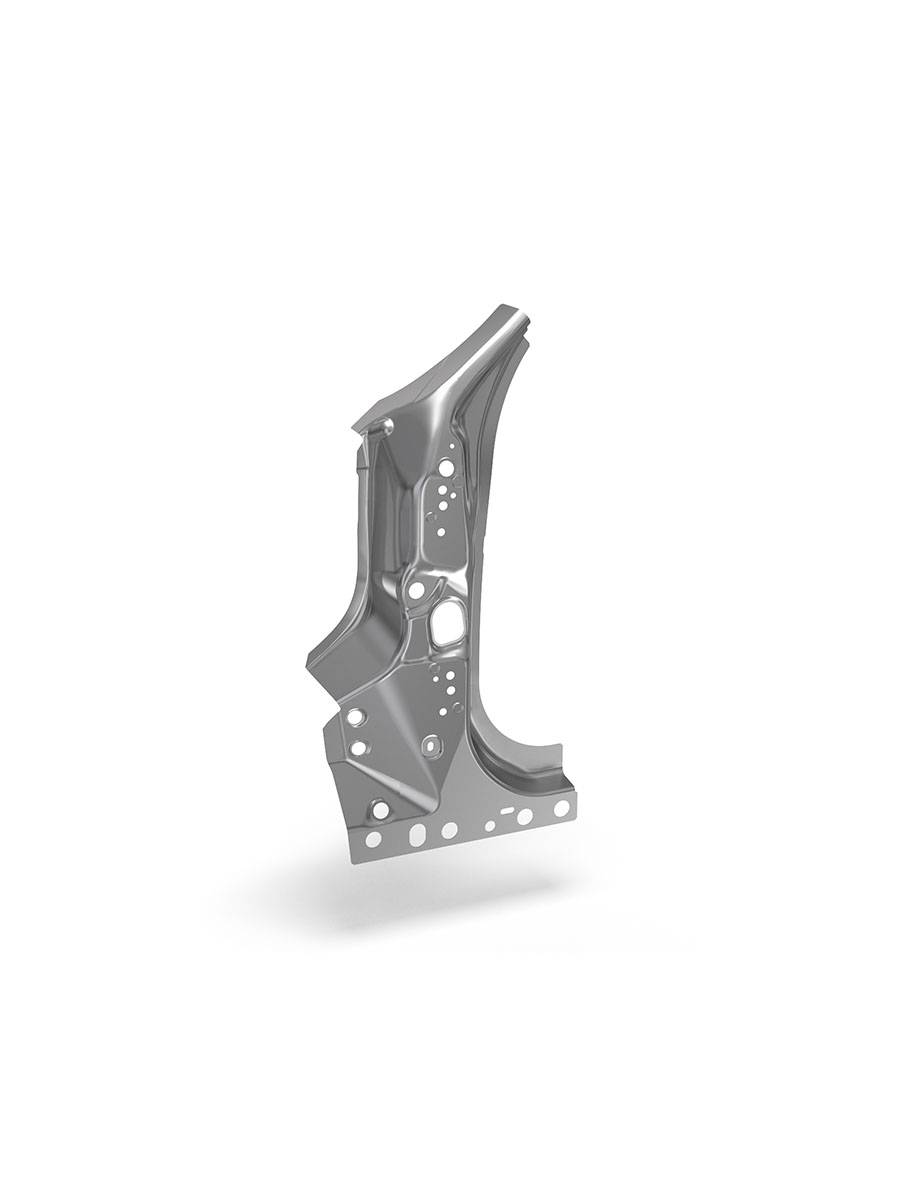

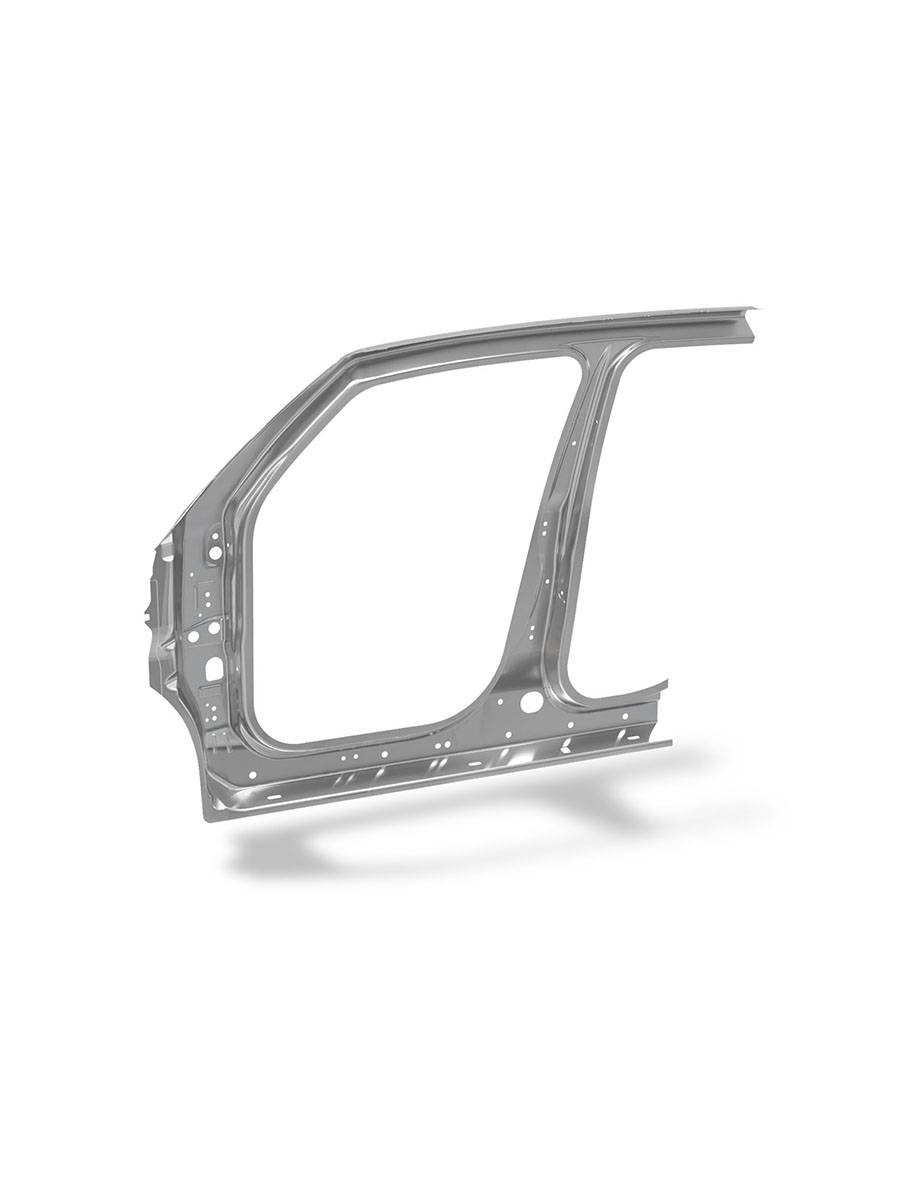

A-PILLAR

Complex feasibility, patches can be added

DOOR IMPACT BEAM

Simultaneous forming and piercing of the part

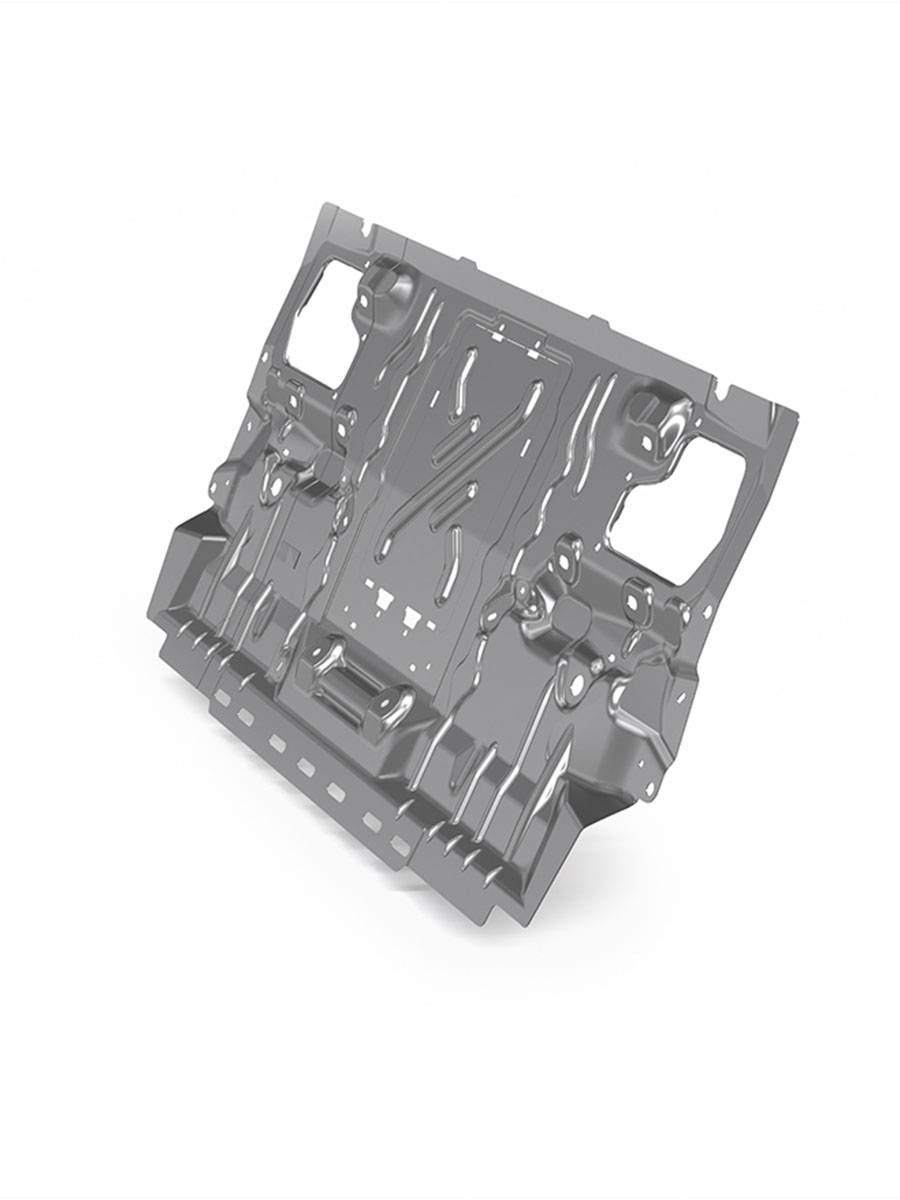

UNDER-SEAT CROSSMEMBER

Part in Ultra-high resistance metal sheet DP1000.

B-PILLAR

Complex feasibility, further technologies can be combined: Tailor Welded Blank TWB, Tailor Rolled Blank TRB, Soft Zone

REAR SIDE MEMBER

Multiple technologies can be combined: Tailor Welded Blank TWB, Tailor Rolled Blank TRB

BUMPER

Complex feasibility and predeveloped trim.

REAR SEAT REINFORCEMENT

Part in TWB. Complex die due to part modularity: interchangeable trimming to implement ski box.

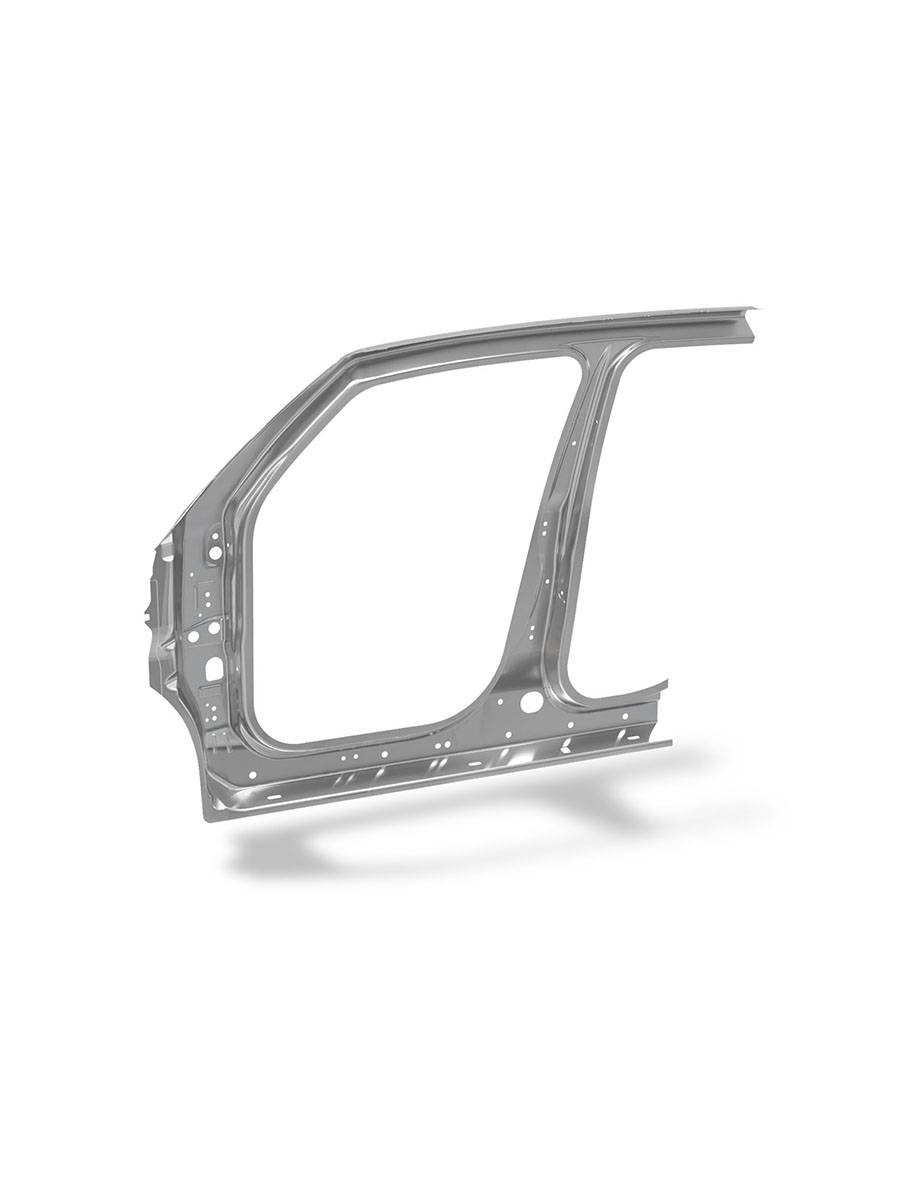

FRONT DOOR FRAME

High quality standard required for this die for aluminium inner frame combined with outer skin.

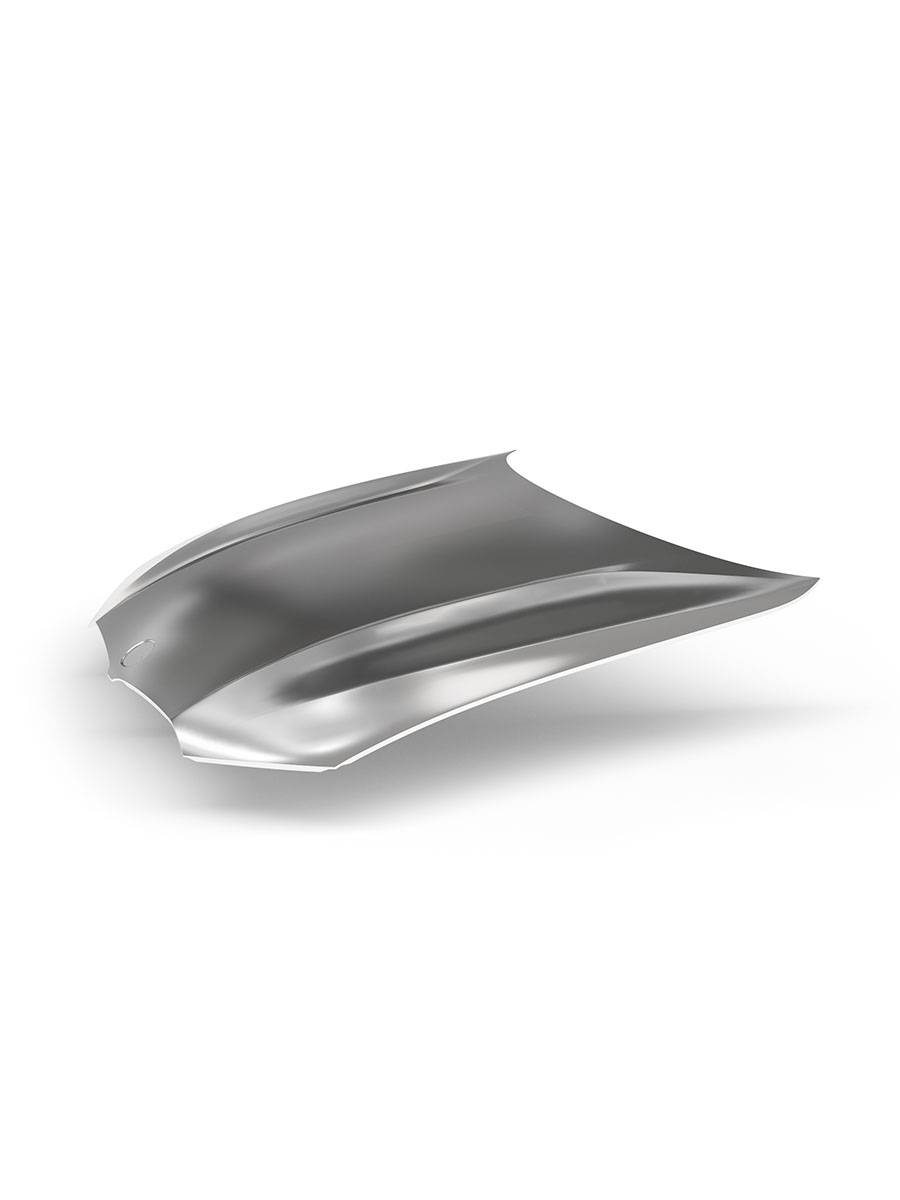

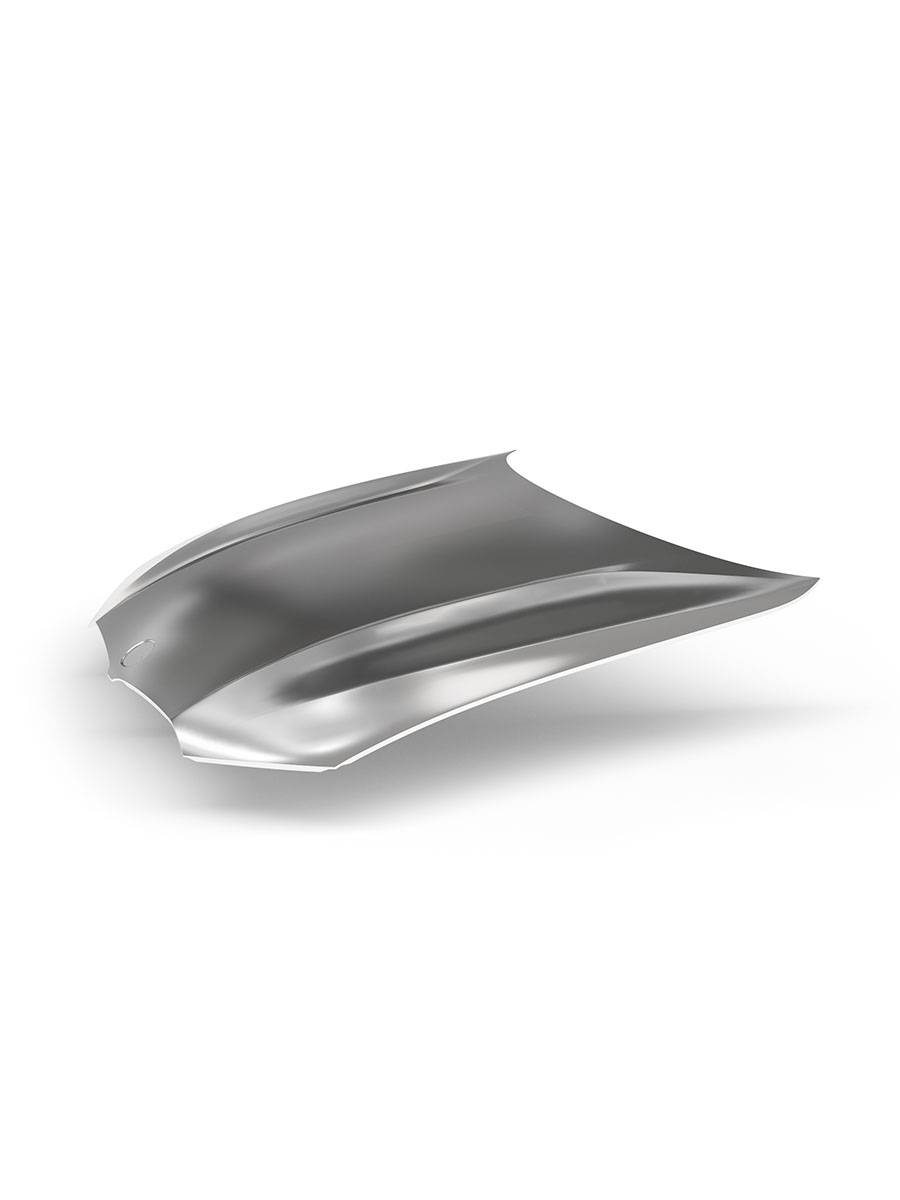

FRONT HOOD PANEL

High quality standard required for this die for outer skin in aluminum sheet.

DOOR RING

Outstanding die with major technological impact combining all side parts in only one part.

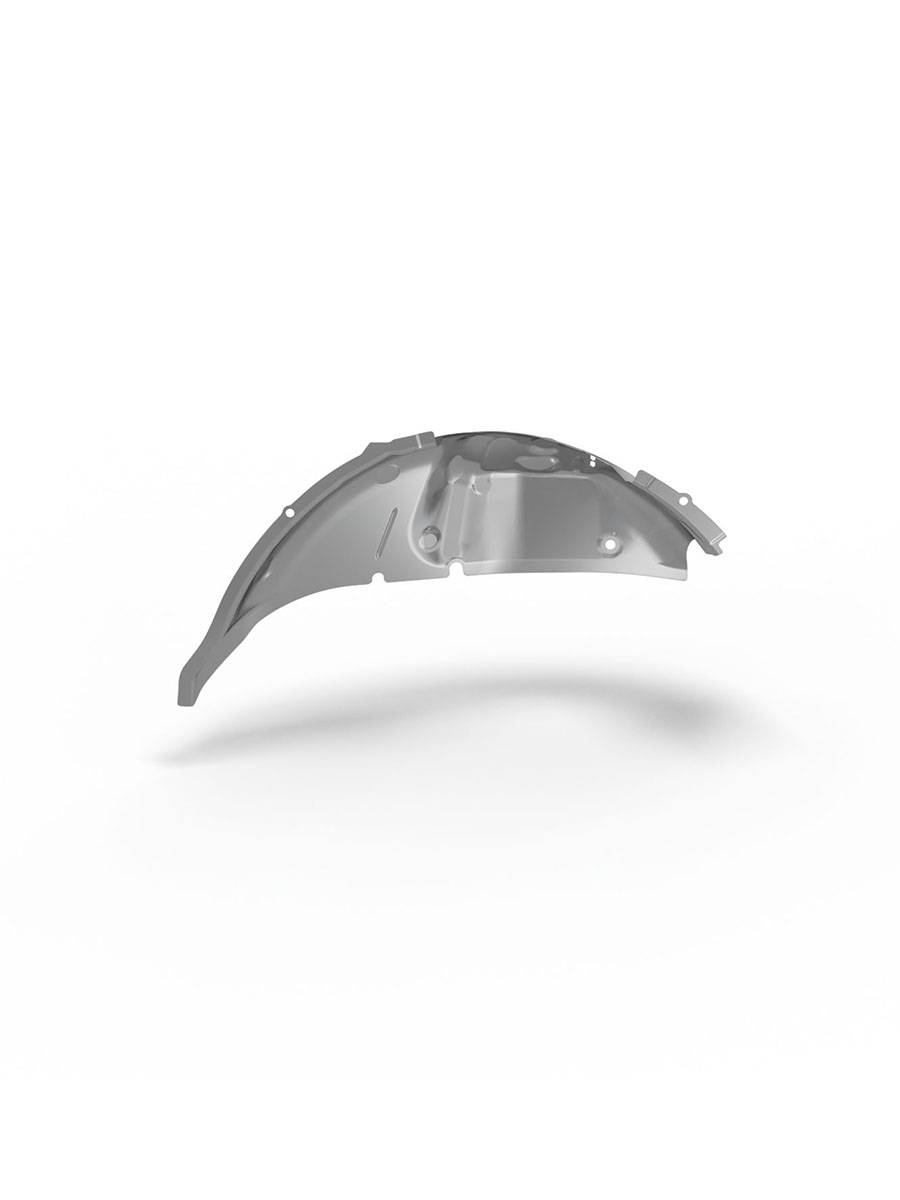

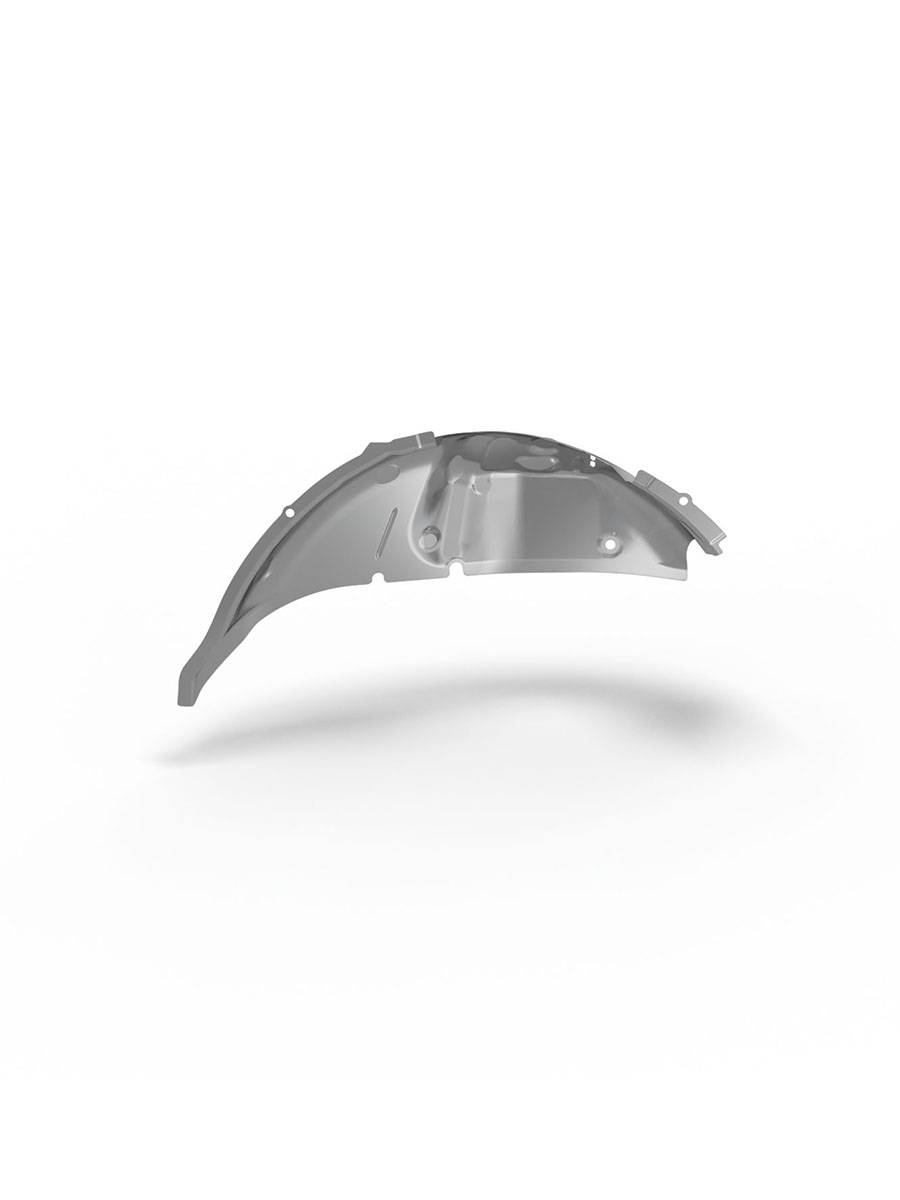

WHEEL ARCH REAR

High quality standard required for this die

FRONT HOOD FRAME

High quality standard required for this die.

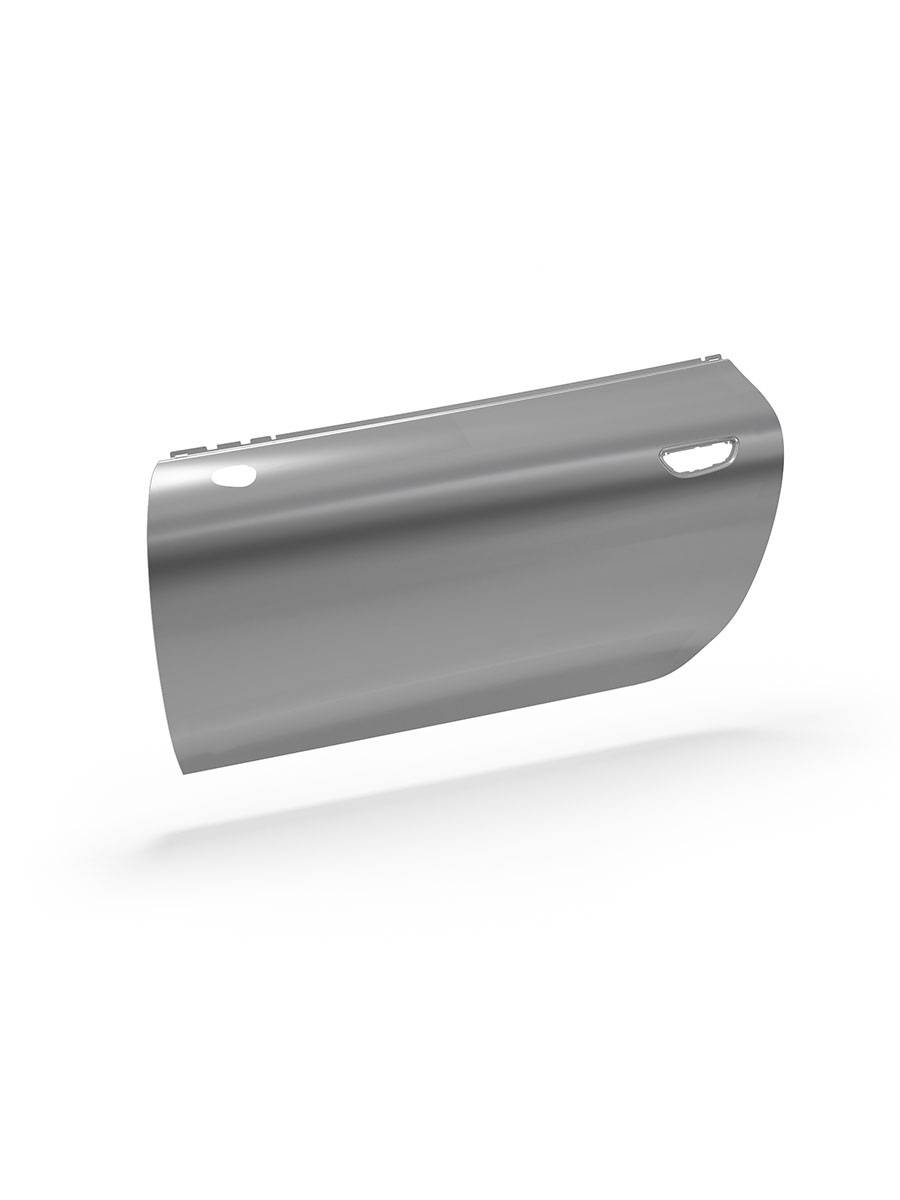

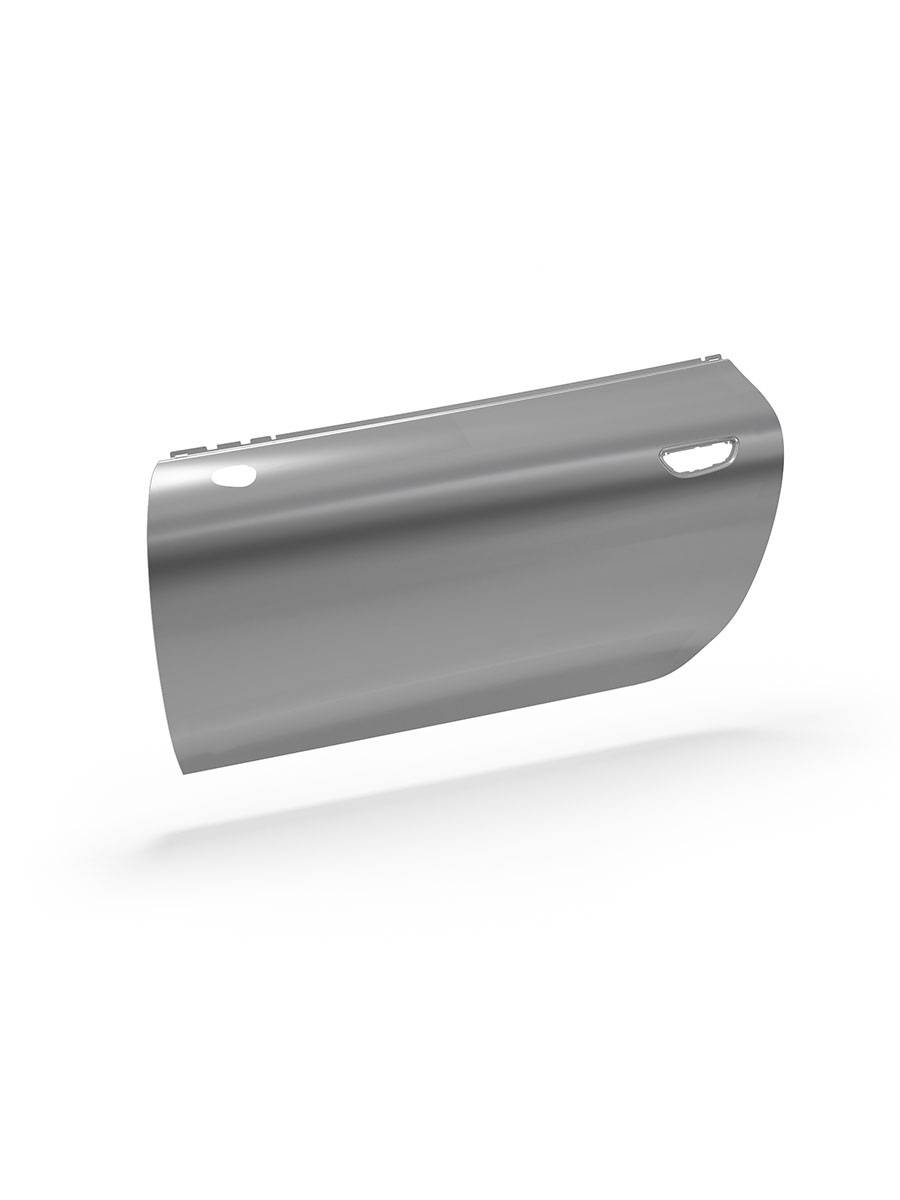

DOOR PANEL

Outer skin in aluminium sheet, high quality standard required for this die.

FRONT WINDOW FRAME

Part stamping is complex due to insert/insertion of standard part and nuts.

WINDSHIELD REINFORCEMENT

Complex geometry due to the different materials stamped like TWB, TRB, co-stamping with carbon parts.

TRUNK FRAME

High quality standard required for this die for aluminium outer skin.

ROOFRAIL REINFOCEMENT

Complex feasibility, Optimization of production with 70% edges definition on the blank

CONTROL ARM

From die casting part to cold formed part. Technical complexity to reach the safety and geometrical standards the OEMs ask.

TUNNEL

Technical complexity due to the springback related to part feasibility

A-PILLAR

Complex feasibility, patches can be added

DOOR IMPACT BEAM

Simultaneous forming and piercing of the part

B-PILLAR

Complex feasibility, further technologies can be combined: Tailor Welded Blank TWB, Tailor Rolled Blank TRB, Soft Zone

REAR SIDE MEMBER

Multiple technologies can be combined: Tailor Welded Blank TWB, Tailor Rolled Blank TRB

BUMPER

Complex feasibility and predeveloped trim.

DOOR RING

Outstanding die with major technological impact combining all side parts in only one part.

WINDSHIELD REINFORCEMENT

Complex geometry due to the different materials stamped like TWB, TRB, co-stamping with carbon parts.

ROOFRAIL REINFOCEMENT

Complex feasibility, Optimization of production with 70% edges definition on the blank

CONTROL ARM

From die casting part to cold formed part. Technical complexity to reach the safety and geometrical standards the OEMs ask.

ROOF FRAME

High quality standard required for this die for aluminium part.

UNDER-SEAT CROSSMEMBER

Part in Ultra-high resistance metal sheet DP1000.

REAR SEAT REINFORCEMENT

Part in TWB. Complex die due to part modularity: interchangeable trimming to implement ski box.

FRONT DOOR FRAME

High quality standard required for this die for aluminium inner frame combined with outer skin.

FRONT HOOD PANEL

High quality standard required for this die for outer skin in aluminium sheet.

WHEEL ARCH REAR

High quality standard required for this die

FRONT HOOD FRAME

High quality standard required for this die.

DOOR PANEL

Outer skin in aluminium sheet, high quality standard required for this die.

FRONT WINDOW FRAME

Part stamping is complex due to insert/insertion of standard part and nuts.

TRUNK FRAME

High quality standard required for this die for aluminium outer skin.